|

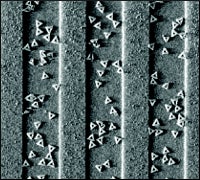

| Detail of triangular DNA origami onto which chip components are bound. Source: IBM |

DNA has long been known as one of the key building blocks of the human body. Now, IBM is also exploring using DNA to help build next-generation computer chips.

The work by scientists at IBM (NYSE: IBM) and the California Institute of Technology said their new findings could yield a significant breakthrough in driving more power and speed into chips, while cutting costs and improving energy efficiency.

The idea centers around using DNA structures — which the scientists dub “origami” — to help create miniscule “scaffolding” on which chips can be built.

Developing ways to make chips smaller is a key hurdle for the semiconductor industry, which has for years continued to drive improvements in performance and energy efficiency by increasingly squeezing more circuits into smaller areas.

IBM pointed out that the industry today is struggling to develop chip-writing technology smaller than 22 nanometers — prompting it to explore approaches like using transistors made of carbon nanotubes or silicon nanowires.

In the IBM and Caltech plan, millions of carbon nanotubes could self-assemble into tiny circuit boards by sticking them to DNA molecules. The end result could see the industry moving beyond the 22nm limit, IBM said.

“The cost involved in shrinking features to improve performance is a limiting factor in keeping pace with Moore’s Law and a concern across the semiconductor industry,” said Chandrasekhar “Spike” Narayan, science and technology manager at IBM’s Almaden Research Center, referring to the widely cited “law” described by Intel co-founder Gordon Moore.

According to the current take on Moore’s Law

“The combination of this directed self-assembly with today’s fabrication technology eventually could lead to substantial savings in the most expensive and challenging part of the chip-making process,” Narayan said.

IBM said Caltech had developed the technique for preparing the DNA and forming it into shapes useful for attaching nanoscale components, while Big Blue developed ways to use traditional chipbuilding technology to etch out patters on the resulting framework.

IBM and Caltech scientists plan to publish their findings in the September issue of Nature Nanotechnology. The issue is currently available online.